Company profile

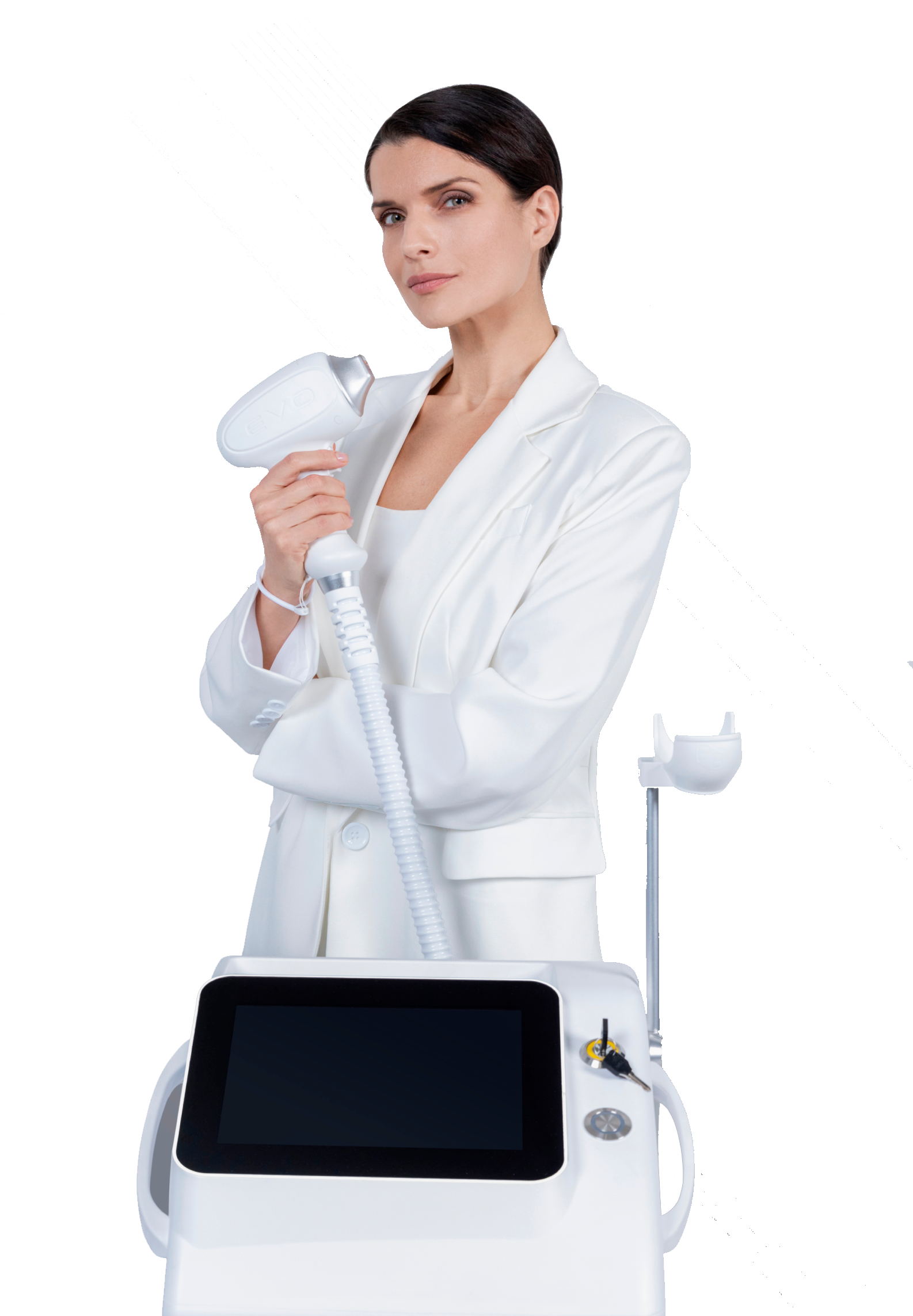

ICBTech is an international company which manufactures high-tech devices for cosmetology and aesthetic medicine.

Laser technology and state-of-the-art software development are the cornerstone of our business.

We ship our devices to beauty salons, laser hair removal centres and aesthetic medicine studios all over the world.

We only work with internationally recognised and proven component suppliers.

This includes companies such as:

This includes companies such as:

Suppliers/components

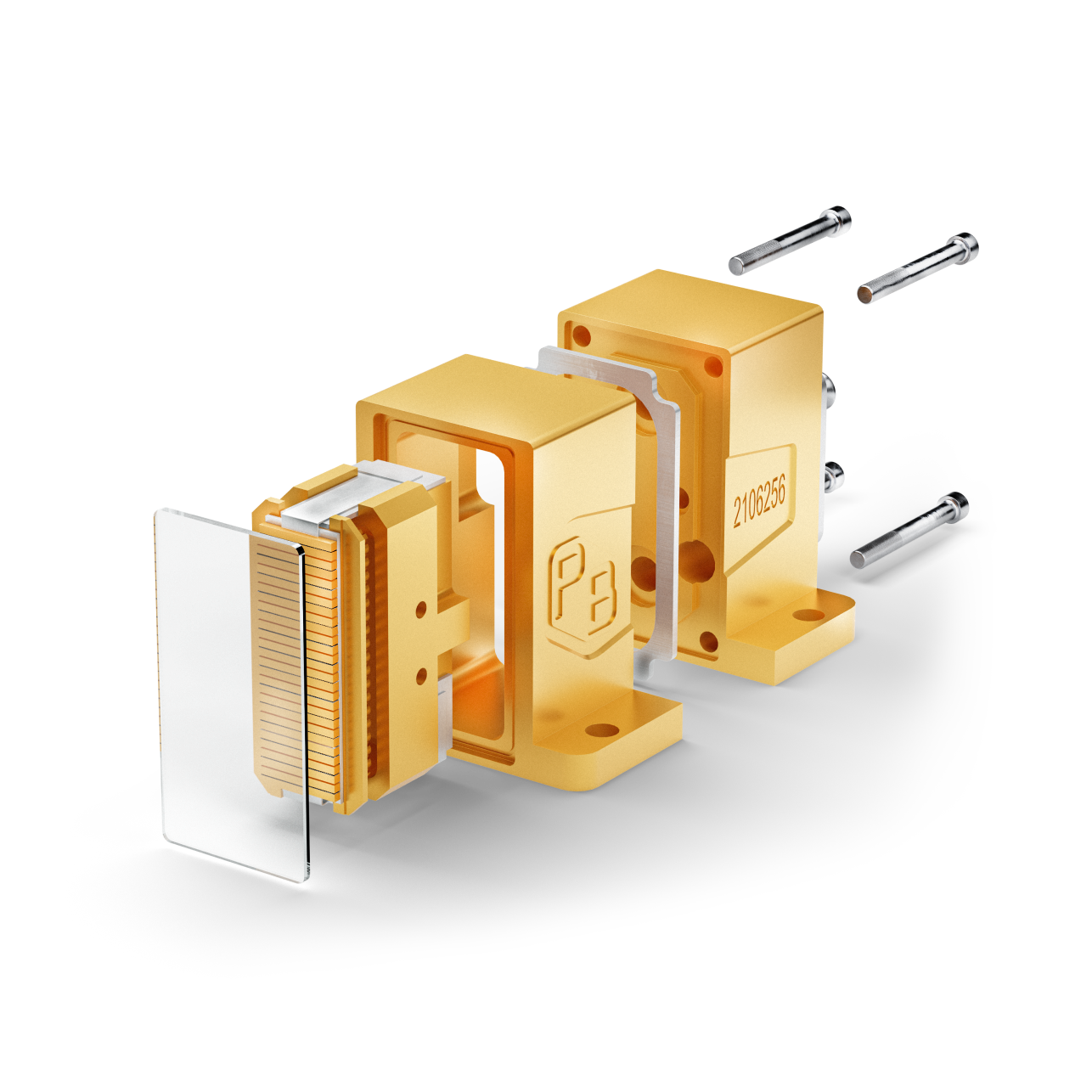

The German leader in laser technology, supplies us with Diodes

Jenoptic

Jenoptic

Jenoptic

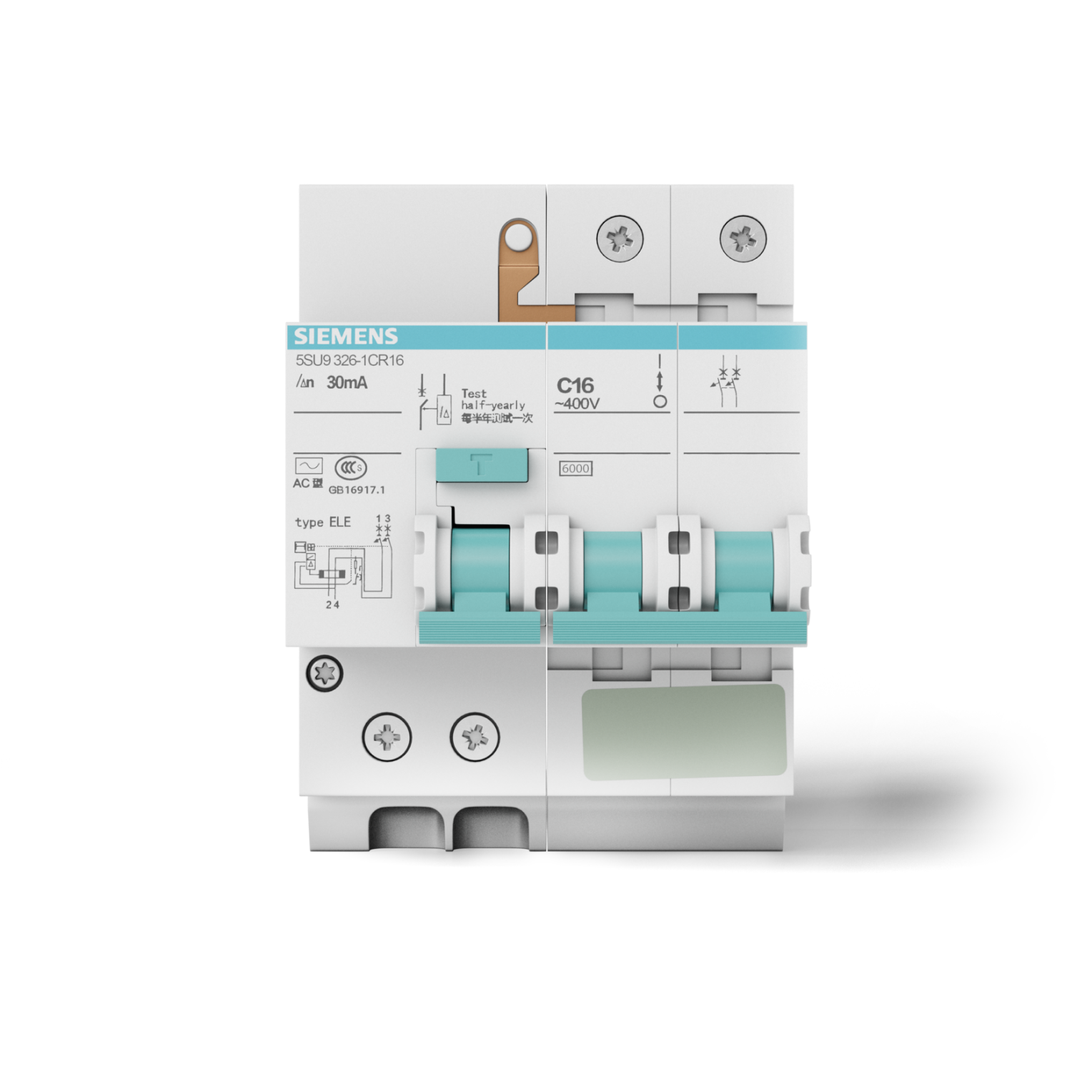

A leader in instrumentation and power supply elements, supplies us with automation and electronic protection of devices

Siemens

A company that supplies complete power supply solutions.

Mean Well

ICBTech

In critical situations, our customers do not have to wait very long for spare parts from the factory. We provide our distributors with a full set of spare parts for modular repairs.

If a part fails, the service centre can replace the entire module at once. Spare parts are also always available in stock. There is no need to wait a very long time for spare parts to arrive in a particular country or city.

If a part fails, the service centre can replace the entire module at once. Spare parts are also always available in stock. There is no need to wait a very long time for spare parts to arrive in a particular country or city.

Our customers are always assured of the quality of our products, as the company provides a warranty of up to five years and after-sales service. The certified service centres of our distributors provide maintenance to our customers.

Our team

Currently our team consists of over 150 people in different departments.

We also pay a great deal of attention to excellent packaging and decorative elements.

Our designers develop unique product concepts, optimize the exterior and the internal structure of our devices. They are in constant search of the new solutions perfection.

For the production of the enclosure elements, we use only high-quality, environmentally friendly plastic and durable but lightweight metal.

3D modellers create 3D models of the devices with clear parameters, correctly integrate all the internal elements of the device, such as the power unit, power supply, control boards, etc., into the enclosure.

These models are then handed over to specialists in the production facility, where the original moulds are created for us, and the casing elements are produced.

These models are then handed over to specialists in the production facility, where the original moulds are created for us, and the casing elements are produced.

Each member of staff ensures that assembly procedures are adhered to, and in the final stages, the units are subjected to a comprehensive inspection by quality control staff.

The employees in the assembly department assemble everything by hand, each having their own task and segment.

As a result of feedback from our customers, our devices are becoming more and more sophisticated, allowing us to meet the needs of our customers at a higher level.

Our engineers pay special attention to the needs of the user when designing our machines.

They also develop and improve the CRM system integrated into our machines, set up high-quality wi-fi to transfer data from the machine, to monitor the functioning of particularly important systems.

IT specialists implement smart algorithms for all systems to ensure that everything runs smoothly and at optimum performance.

But before serial production begins, the product must be assessed for compliance with legal requirements, and before it is shipped to our customers, our service centre conducts pre-sale preparation of the devices testing and checking all modules, assemblies, and making the necessary measurements

Quality control specialists check all systems and test apparatuses

Three-stage quality control involves:

Three-stage quality control involves:

- Control of purchased components (raw materials, packaging materials), on arrival at the facility

- Supervision of all production steps

- Control of the finished product before dispatch to the client